Precision Cast Iron CNC Machining in New England — Get a Fast, Expert Quote

Looking for reliable, high-precision cast iron CNC machining in New England? Mountain Machine Works delivers expert craftsmanship and quick turnaround for local manufacturers, engineers, and fabricators who demand nothing less than excellence.

Why Choose Mountain Machine Works for Your Cast Iron CNC Projects?

- Decades of experience serving the New England manufacturing community

- State-of-the-art CNC machining centers for complex geometries and tight tolerances

- Fast quotes, transparent pricing, and on-time delivery — every project, every time

What is Cast Iron CNC Machining?

Cast iron CNC machining is a subtractive manufacturing method that enables extremely precise production of complex parts from castings, round bar or plates of cast iron.

The process begins with a Computer Numerical Control (CNC) machine, which can be programmed to accurately cut components out of the block of material in accordance with a specification.

This allows for the manufacture of parts with complex geometries and precise tolerances that cannot be as easily achieved with conventional manual machining or molding methods.

CNC machining also offers low setup time and cost savings due to the high precision of the components produced, making it an attractive option for shorter production runs or when time is limited. As the demand for reliable and accurate components continues to rise, cast iron CNC machining is quickly becoming one of the most commonly used processes in modern manufacturing.

The Benefits of Using Cast Iron for CNC Machining Projects

What Finishes Are Available for Cast Iron Parts Produced Using CNC Machining

In addition to the benefits mentioned above, cast iron CNC machining can also be used to produce parts with a range of finishes. At Mountain Machine Works, we offer a wide range of finish options for our cast iron CNC machining projects.

Our finishes include:

Powder Coating

This finish provides an even finish and is perfect for projects where aesthetics are important.

Polishing

We can polish any part to create a smooth, shiny finish with minimal reflective properties.

Sandblasting

This is a great way to add texture and create a unique look for your parts.

Heat Treatment

We can heat treat cast iron components to improve their strength and durability.

Trusted by Maine Manufacturers — Your Local Partner

Our customers include local machine shops, industrial facilities, and OEMs throughout Maine and New England. Ask about our recent projects and references!

Your satisfaction is our promise. We stand behind every part we produce — if it’s not right, we’ll make it right.

By utilizing our state-of-the-art CNC machining centers, we are able to provide the highest quality parts and finishes for any project.

Our experienced team is ready to help you create exactly what you need with the highest level of precision.

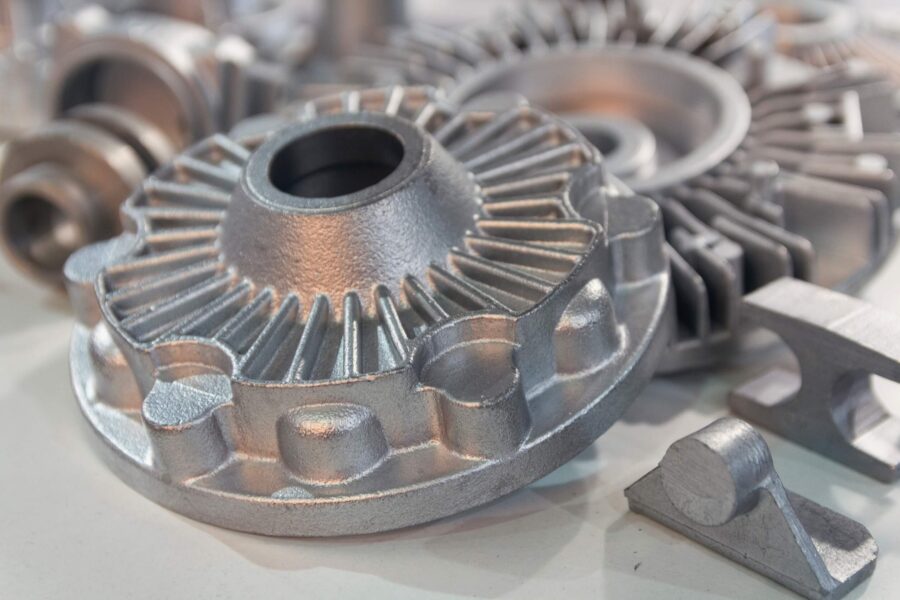

Types of Parts That Can Be Machined Using Cast Iron CNC Machining

While many materials, such as aluminum and steel, are commonly used for CNC machining, cast iron is also a great choice for many applications. It can be used to produce a variety of parts with complex geometries and precise tolerances, including:

- Valves: Cast iron is often used for valves due to its strength and durability.

- Gears: CNC machining allows for the creation of gears with complex geometries and precise tolerances.

- Pumps: Cast iron is perfect for pumps due to its corrosion-resistance.

- Shafts: Shafts machined out of cast iron are strong and can withstand heavy loads.

- Bearings: CNC machining allows for the production of bearings with precise dimensions that are durable and long-lasting.

Industries That Rely on Precision Machined Cast Iron Parts

Machined cast iron components are essential across a wide range of industries, thanks to their strength, durability, and ability to maintain tight tolerances. Some of the key sectors that frequently utilize precision machined iron and cast iron parts include:

Medical Equipment Manufacturing: For robust components in imaging machines, surgical instruments, and diagnostic devices.

Aerospace and Defense: Precision parts are crucial in both commercial and military aircraft, as well as various aerospace control systems.

Industrial Machinery: Heavy equipment and machines, including those used in manufacturing lines, depend on cast iron for reliability under high loads.

Semiconductor Manufacturing: Specialized cast iron components help maintain accuracy in the production of electronics and microchips.

Oil & Gas: Critical applications in drilling, pumping, and processing equipment rely on cast iron parts for their heat and corrosion resistance.

Automotive: From engine blocks to brake components, cast iron delivers strength and wear resistance for a wide variety of vehicle parts.

Electronics: Precision housings and structural elements in electronic assemblies benefit from the rigidity of cast iron.

Pneumatics and Hydraulics: Pressure vessels, valves, and cylinders crafted from cast iron ensure long service life in demanding fluid power systems.

Food Processing: Machinery for food production often uses cast iron because it is durable and easy to sanitize.

Heavy Construction Equipment: Load-bearing parts in bulldozers, cranes, and excavators are often produced from cast iron for their reliability.

By supporting these diverse industries, cast iron CNC machining proves to be a versatile solution for any application that demands both performance and precision.

What Types of Cast Iron Can Be Used for CNC Machining?

One of the most widely-used materials for CNC machining is cast iron, which can be found in many types, such as:

- Grey cast iron: This variety of cast iron has a high carbon content and can be used for applications that require strength and wear resistance.

- Ductile cast iron: Also known as nodular or spheroidal graphite iron, this type of cast iron is more ductile than grey cast iron and is often used when greater ductility and impact strength are needed.

- Malleable iron: Malleable iron is more ductile than grey and ductile cast iron and is often used for components that require greater strength, such as valves and gears.

- White cast iron: This type of cast iron has a very high silicon content, making it harder and more brittle than other types of cast iron. It is often used for applications where high strength and wear resistance are required.

- Compacted graphite iron: This type of cast iron has a higher tensile strength than other varieties and is often used for parts that need to be stronger.

Ultimately, choosing the right cast iron for your application requires an understanding of all the potential advantages each type has to offer.

By working with our experienced team, you can be sure that the right material will be selected for your CNC machining project.

The Challenges of Cast Iron CNC Machining

CNC machining of cast iron is a difficult process due to the many challenges associated with it:

- Abrasive wear is one issue because the hardness of cast iron can lead to teeth on cutting surfaces getting worn away.

- Vibration is another key challenge, which can be caused by different factors such as interference from cooling fluids, inaccurate toolpaths, incorrect speeds and feed rates, or inadequate spindle power and torque.

- There is the risk of thermal deformation and cracking, which can occur when the part is exposed to high temperatures.

- Finally, cast iron is prone to warping, which can affect accuracy and precision.

In order to achieve successful CNC machining of cast iron components, it is essential that the potentially damaging factors are identified and addressed.

This usually entails using higher powered machines and tools with larger cutting surfaces combined with optimizing program settings and improving coolant control systems.

By tackling the challenges effectively, CNC machining of cast iron components can provide manufacturers with higher quality products alongside increased productivity and cost-efficiency.

Tips for How to Overcome Challenges for the Best Results

Instead of getting overwhelmed by these challenges, take a proactive approach to overcoming these hiccups.

- First and foremost, plan out your project scope, timeline, and goals and objectives in detail. Every good project should have a clear plan with measurable milestones; this helps break it down into more achievable tasks, so you can identify problems early on.

- Brainstorm solutions for any issues that arise. Know what tools or resources are available to you that could help get the job done faster or better.

- Communication is key. Ensure all stakeholders are kept up-to-date throughout the project’s development to ensure everyone’s buy-in from start to finish – an informed team will help you get the most out of your project every time.

- Use high-powered machines and tools with larger cutting surfaces for machining. This will make it easier to cut through the material more smoothly, reducing wear on the tools and improving accuracy.

- Set up optimized program settings in order to get precise results from your CNC machine. Setting up a proper feed rate and speed helps to reduce vibrations and improve the quality of the finished product.

- Use a coolant control system in order to keep temperatures down. This will help reduce thermal deformation while also ensuring warping is minimized or eliminated completely.

Some Design Recommendations for Cast Iron CNC Machining

Cast iron CNC machining can be a tricky process and requires precision to achieve an ideal outcome.

It is important to create a good design plan when dealing with cast iron. Cutting and shaping cast iron requires careful considerations due to its hardness, which can lead to tool wear.

When designing for cast iron machining, it’s essential to use proper cutting strategies such as a generous allowance for the cutting tool. It may be beneficial to provide slots that permit the use of thin wall inserts and if possible, using Thin-walled cavity methods are also recommended for its strength.

Lastly, make sure that you select the appropriate tooling for your design in order to avoid problems during machining and help increase productivity.

The Importance of Quality Certifications for Cast Iron Machining

When choosing a partner for your cast iron machining needs, it’s important to look for companies that carry trusted quality certifications. Leading standards like ISO 9001 speak volumes—they show a commitment to rigorous quality management, consistency, and traceability throughout the manufacturing process. These certifications help ensure that each part meets exacting specifications, especially crucial for industries such as aerospace and defense.

In addition to these, ITAR registration is essential for companies handling projects with U.S. defense or military applications. This ensures compliance with export regulations and adds another layer of accountability to every job.

By working with a machining provider certified to these standards, you can feel confident your components will be produced with the highest level of care and professionalism.

Why Mountain Machine Works is Your Go-to for CNC Machining of Cast Iron Parts

When it comes to CNC machining of cast iron parts, Mountain Machine Works has no peer.

With many years in the industry, we have perfected our process through expansive experience and cumulative expertise. Our team of machinists is one of the most knowledgeable and understands the best methods for turning intricate designs into reality, and how to help customers optimize their finished product. Combine that with ultra-modern equipment and you get unbeatable accuracy and outstanding quality – guaranteed.

So if you need cast iron parts that are hassle-free and dependable, choose Mountain Machine Works – your go-to for cast iron CNC machining. Contact us today to learn more.