Precision Aluminum CNC Machining Services for New England Manufacturers

Looking for reliable, high-quality aluminum CNC machining? Mountain Machine Works delivers precision parts—on time, every time—to help your business stay ahead.

Whether you’re an engineer, designer, or production manager, our skilled team in Maine provides advanced aluminum CNC machining tailored to your exact needs. We serve a diverse range of industries—manufacturing, aerospace, marine, and more—throughout New England.

Why Aluminum CNC Machining?

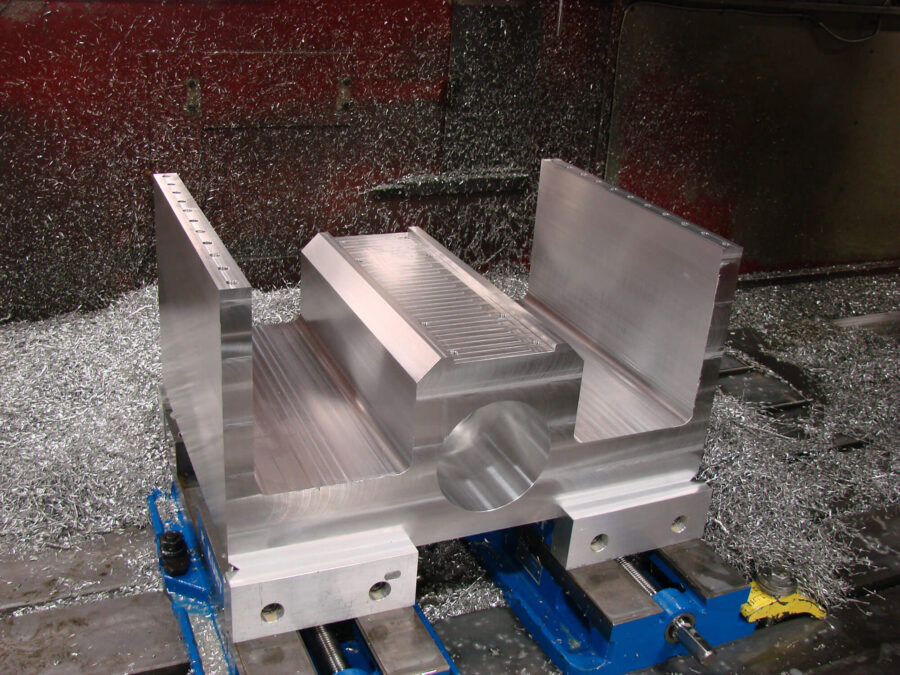

CNC machining with aluminum allows you to achieve complex shapes and exacting tolerances that traditional methods can’t match. Our state-of-the-art CNC machines ensure your parts are precise, consistent, and ready for demanding applications.

There are many advantages of aluminum CNC machining, including:

Why Choose Aluminum for Your Custom Parts

- Aluminum is a soft, lightweight metal that is corrosion-resistant and non-magnetic.

- Aluminum can be coated in numerous processes including anodize type I, II, & III.

- Electroless Nickel and many other coating options are available to improve your products performance. This makes it a popular choice for CNC machining.

What Sets Mountain Machine Works Apart?

- Local Expertise: Proudly serving Maine and New England since 1982, we know the local industry’s demands and tight timelines.

- Quality Assurance: Every part undergoes rigorous inspection—guaranteed accuracy, every order.

- Fast Turnaround: Meet your deadlines with expedited service options.

- Responsive Team: Real people, real answers—call (207)783-6680 or contact us for quick support.

What are the types of aluminum alloys and plates used in CNC machining?

There are a variety of aluminum alloys and plates that can be used for CNC machining, each with its own unique set of properties. Cast alloys of aluminum are designated by a four-digit system. The first digit indicates the major alloying element, the second digit indicates the degree of purity for the base aluminum, and the third and fourth digits just designate individual alloys. Aluminum plates are machined products ideal for tooling and base plates.

2024 Aluminum

The 2024 aluminum alloy is an alloy made of copper, magnesium, manganese, and trace impurity elements. It is a high-strength alloy that is frequently used in vehicle and aircraft construction. It has a high strength-to-weight ratio and outstanding fatigue resistance. It can be machined to a high finish and formed with subsequent heat treatment in the annealed condition. Common applications include truck wheels, structural aircraft parts, gears, cylinders, and pistons.

6061 Aluminum

The 6061 aluminum alloy is heat-treatable and flexible while maintaining excellent aluminum characteristics. It has a wide range of mechanical properties and resistance to corrosion. It is weldable, can be brazed with a furnace, and has excellent workability in the annealed condition. 6061 aluminum alloy is used in a wide range of applications, including welded assemblies, marine hardware, aircraft and truck parts, chemical equipment, electronic parts, furniture, fasteners, heat exchangers, heat sinks, and food processing equipment.

7075 Aluminum

The 7075 aluminum alloy has a much higher strength-to-weight ratio than many other alloys, making it ideal for use in high-stress applications. In the annealed condition, this grade can be formed and heat-treated if necessary. Its cost is typically higher than other alloys due to its high strength. Common applications include aircraft fittings, gears and shafts, missile parts, regulating valve parts, worm gears, as well as aerospace and defense applications.

MIC-6 Aluminum Plate

Aluminum MIC-6 is a cast plate known for its stability and consistency between plates, superior flatness and dimensional tolerances on the thickness. Popular for tooling and base plates due to the stability and resistance to wear.

Cast Aluminum Jig Plate

The cast jig plate is a machined plate made from cast aluminum. It is stress-relieved to provide sound dimensional stability and minimal or no distortion, even after extensive machining operations. It is a cost-effective alternative to other alloys. Common applications include tooling, fixtures, and jigs.

What are finishing options for CNC-machined aluminum parts?

There are a variety of finishing options available for CNC-machined aluminum parts, including:

Anodizing

Anodizing is a type of aluminum finishing that creates a protective layer on the aluminum surface. This layer can be dyed to create a wide range of colors.

Painting

Painting is another popular aluminum finishing option. It can be used to create a wide range of colors and effects.

Powder Coating

Powder coating is a type of aluminum finishing that creates a durable, protective layer on the aluminum surface.

Plating

Plating is a type of aluminum finishing that involves bonding a thin layer of metal to the aluminum surface. This can be done for a variety of reasons, including to improve the aluminum's appearance or to protect it from corrosion.

Types of Anodizing for Aluminum Parts

Anodizing is a surface treatment used to thicken the natural oxide layer on aluminum parts. The anodizing process makes aluminum parts more corrosion resistant and wear resistant, and also provides better adhesion for primers and glues than bare aluminum. Anodizing is usually performed after machining aluminum parts, as it can improve the finish of the parts and help protect them from wear.

There are three main types of anodizing for aluminum parts:

Type 1 (Chromic Acid Anodizing)

Creates a thin, protective layer on the aluminum surface. It is often used for parts that need to be corrosion resistant and won't damage or fatigue the aluminum.

Type II (Sulfuric Acid Anodizing)

Creates a thin, protective layer on the aluminum surface that can be dyed to create a wide range of colors.

Type III (Sulfuric Hard Anodizing)

Creates a thicker, more durable layer on the aluminum surface that can also be dyed. With a hardness of up to 70 Rockwell, it is often used for parts that will be exposed to high wear and tear.

What applications is aluminum CNC machining used for?

Aluminum CNC machining can be used for a wide range of applications, including:

- Automotive parts: Aluminum is often used to create lightweight automotive parts, such as wheels and suspension components.

- Aerospace parts: Aluminum is the material of choice for many aerospace applications because of its strength and durability.

- Medical devices: Aluminum is often used to create medical devices because of its biocompatibility and resistance to corrosion.

- Electrical components: Aluminum is a good conductor of electricity, so it is often used to create electrical components, such as wiring and circuit boards.

Why do designers and engineers choose aluminum and aluminum alloys?

There are many reasons why designers and engineers choose aluminum and aluminum alloys for CNC machining. Some of the advantages of aluminum machining include:

- Aluminum is a lightweight material that is easy to work with and transport.

- Aluminum has a high strength-to-weight ratio, meaning it is strong yet light.

- Aluminum is corrosion resistant and does not rust.

- Aluminum has a low melting point, making it easy to work with and shape.

- Aluminum is a good conductor of heat and electricity.

- Aluminum can be recycled and reused.

- Aluminum is a relatively soft metal that is easy to machine.

- Aluminum can be anodized to create a variety of colors.

- Aluminum CNC machining can be used to create parts with intricate designs and detailed features.

The Benefits of Combining CNC Machining with Other Aluminum Manufacturing Processes

When it comes to producing high-quality aluminum parts—especially in larger runs—it’s not always best to rely solely on CNC machining. Pairing CNC machining with other manufacturing methods like extrusion, forging, or casting can unlock new efficiencies, improve part strength, and enable the creation of more intricate shapes.

Let’s break down how each process can work hand-in-hand with CNC machining:

Aluminum Extrusion and CNC Machining

Aluminum extrusion is all about pushing heated aluminum through a die to create long pieces with continuous profiles—think window frames or heatsinks made from alloys like 6061. While extrusion delivers the basic shape efficiently, CNC machining provides the finishing touch, allowing for details, cutouts, or custom features that are hard to achieve with extrusion alone. This combo is ideal for producing robust parts with complex cross-sections or irregular geometries.

Forging and CNC Machining

Forging involves molding aluminum alloys into shape by applying intense compressive force (imagine blacksmithing on an industrial scale). The result? Parts with superior strength and grain structure. CNC machining then fine-tunes the forged component, refining tolerances, adding holes, or detailing features. This two-step approach is especially valuable when strength, durability, and precision are top priorities—like in aerospace or performance automotive applications.

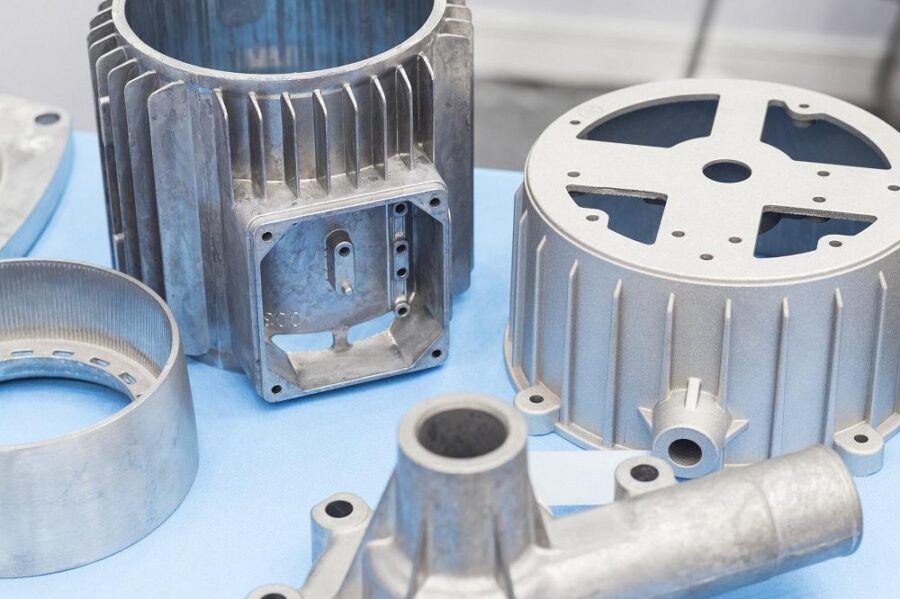

Casting and CNC Machining

Processes such as investment casting and die casting allow manufacturers to create intricate aluminum parts in high volumes. Investment casting uses wax patterns to produce near-net shape parts with excellent surface finishes, while die casting injects molten aluminum into steel molds under pressure. After casting, CNC machining steps in to perfect surfaces, critical dimensions, and any features not feasible during casting. This marriage of methods delivers parts that are both complex in shape and highly precise, making it popular for everything from intricate housings to engine components.

Why Combine Methods?

Blending CNC machining with extrusion, forging, or casting brings together the strengths of each process. The result:

- Greater material efficiency—less waste, especially when starting with near-net shapes.

- Improved mechanical properties—like the increased toughness of forged components.

- More freedom in part design—enabling complex features or tight tolerances.

- Cost savings, particularly for medium to large production runs.

By thoughtfully combining these manufacturing techniques, designers and engineers can create aluminum parts that meet strict performance requirements, keep costs in check, and take full advantage of aluminum’s natural benefits.

What is the process and benefit of aluminum extrusion combined with CNC machining?

Aluminum extrusion is a manufacturing method that involves pushing heated aluminum through a die to create long shapes with consistent cross-sections—think of it as squeezing toothpaste out of a tube, but with more precision and engineering involved. These extruded profiles can range from simple rods to intricate channels and custom designs.

Once the raw extruded aluminum section is created, CNC machining steps in to bring out finer details. By cutting, drilling, and shaping, CNC machines transform the basic extruded piece into a finished part matching your precise specifications. This two-step process enables the creation of components that are both structurally sound and highly detailed.

Benefits of combining these two methods:

- Efficiency: Extrusion allows for quick production of base shapes, while CNC machining adds technical features like holes, threads, or slots.

- Design Flexibility: Complex geometries and unique cross-sections are achievable that would be difficult or costly to make using machining alone.

- Material Optimization: Popular aluminum alloys used in extrusion, such as 6061, are well-suited for both processes. They offer strength, corrosion resistance, and machinability—making them an industry favorite from race car chassis to aircraft fittings.

- Cost-Effectiveness: Producing the initial profile through extrusion saves time and raw material, with CNC finishing providing the necessary specificity.

Together, extrusion and CNC machining offer a powerful combination for makers and engineers aiming for both scale and precision in their aluminum parts.

How can die casting and CNC machining be used together for aluminum components?

For projects requiring both high volume and detailed precision, die casting and CNC machining can work hand-in-hand. The process typically starts with die casting, where molten aluminum is injected into hardened steel molds under high pressure. This manufacturing method is ideal for producing large quantities of uniform shapes efficiently, especially for intricate part designs.

Once the basic component is formed through die casting, CNC machining steps in to refine and customize the part. Using state-of-the-art machining centers—equipped with precise cutting tools—our team can add detailed features, drill holes, cut threads, refine surfaces, or machine complex geometries that would be challenging to achieve through die casting alone.

This combination allows manufacturers to take advantage of the speed and cost-effectiveness of die casting, while also benefiting from the versatility and accuracy of CNC machining for final details. The result: finished aluminum parts that not only meet exact tolerances but also feature smooth surfaces and complex details, ready for critical automotive, aerospace, electronic, or medical applications.

What are the advantages of investment casting combined with CNC machining for aluminum parts?

Pairing investment casting with CNC machining brings several benefits when working with aluminum parts:

- Exceptional Surface Finish: Investment casting produces parts with smooth surfaces right from the mold, minimizing the need for extensive post-processing.

- High Dimensional Precision: When tight tolerances are essential, CNC machining is used to refine and complete cast parts, delivering highly precise results.

- Complex Geometries: Investment casting enables the production of intricate and detailed shapes—designs that are often difficult or costly to achieve with traditional machining alone.

- No Parting Lines: Unlike other casting processes, investment casting leaves no unsightly parting lines or flash, further enhancing the appearance and performance of aluminum components.

- Material Versatility: A wide range of aluminum alloys can be used, allowing designers to select the right balance of strength, weight, and corrosion resistance for their project.

By combining both processes, manufacturers can efficiently produce aluminum parts that are complex, accurate, and ready for critical applications. This method is especially valuable in industries where both aesthetics and performance matter—such as aerospace, automotive, and medical device manufacturing.

How does forging combined with CNC machining enhance aluminum components?

Forging followed by CNC machining is a valuable approach for manufacturing aluminum parts that require both exceptional strength and precision. Forging uses intense compressive forces to shape raw aluminum. This process aligns the metal’s internal grain structure, resulting in increased toughness and improved mechanical properties—think of components for automotive and aerospace applications that need to withstand high loads or repeated stress.

Once the forging process creates a strong, durable blank, CNC machining is then used to achieve final shapes and intricate details that forging alone can’t provide. By combining both methods, manufacturers can produce aluminum parts that offer the best of both worlds:

- Superior strength: Forged aluminum is less likely to crack or fail under stress than cast or solely machined parts.

- Precision and detail: CNC machining enables the production of complex geometries, tight tolerances, and smooth finishes.

- Cost-efficiency: Forging often reduces material waste and speeds up production, especially for high-volume or repetitive parts.

With this approach, designers and engineers can reliably create high-performance aluminum components ideal for demanding industries.

Fast Turnaround on Custom Aluminum Machined Parts

Need your custom aluminum components in a hurry? With our streamlined processes and advanced CNC technology, we can deliver machined aluminum parts in as little as 3 days—helping keep your project moving on schedule. Whether you require a one-off prototype or a batch of production parts, we’re equipped to handle your needs quickly and efficiently, without sacrificing quality or precision.

No Minimum Order Quantity (MOQ) for Aluminum Machining

Whether you need a single aluminum prototype or a full production run, our flexible services are designed to meet your project requirements—no minimum order quantity required. We accommodate orders of any size, allowing you to move quickly from concept to finished part without the burden of large commitments. This versatility ensures that whether you’re developing a one-off concept or scaling up for volume manufacturing, you’ll receive the same attention to detail and service quality every time.

Contact our experienced team today.

To learn more about aluminum CNC machining and how we can help you with your next project, contact the experienced team at Mountain Machine Works.

We are proud to offer complete CNC machining services for aluminum parts, including aluminum milling, aluminum turning, and large part machining with aluminum. Our state-of-the-art equipment and experienced team can handle projects of all sizes, from small prototype runs to production orders.

Request a quote today.