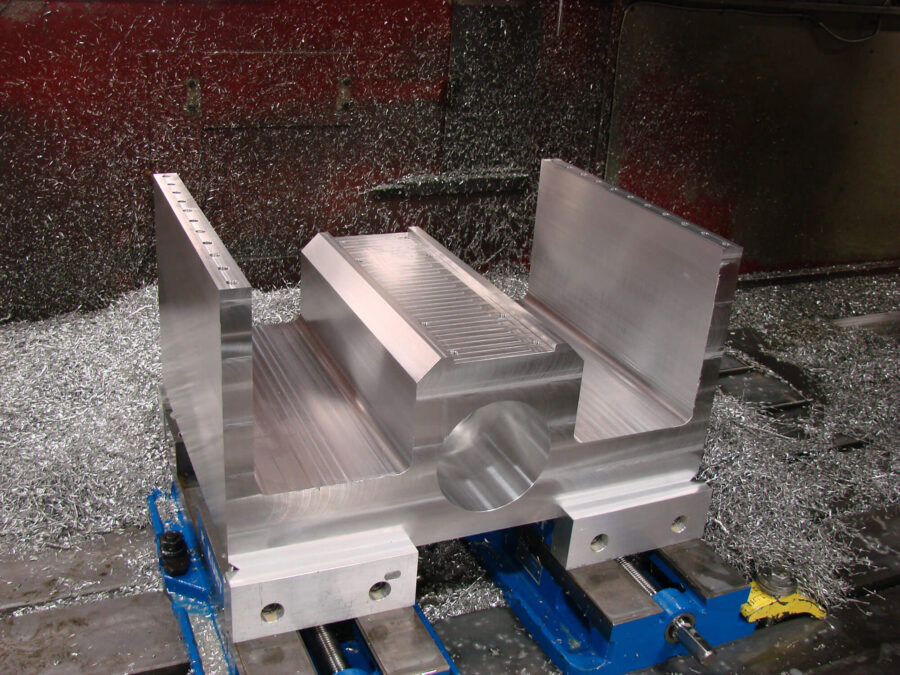

Aluminum CNC Machining Services

The skilled team at Mountain Machine Works provides a variety of aluminum CNC machining techniques that will meet your needs.

Read on to learn what CNC machining for aluminum parts is, the different types of aluminum used in CNC machining, and the most common aluminum CNC machining processes.

We’ll also explore why designers and engineers choose aluminum and aluminum alloys for CNC machining and milling parts and the advantages of Mountain Machine Works’ complete CNC services with aluminum.

What is Aluminum CNC Machining?

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape material according to a set of programmed instructions. CNC aluminum machining is ideal for creating parts with complex shapes and precise dimensions that would be difficult or impossible to create using traditional methods like manual machining.

There are many advantages of aluminum CNC machining, including:

Why Choose Aluminum for Your Custom Parts

- Aluminum is a soft, lightweight metal that is corrosion-resistant and non-magnetic.

- Aluminum can be coated in numerous processes including anodize type I, II, & III.

- Electroless Nickel and many other coating options are available to improve your products performance. This makes it a popular choice for CNC machining.

What are the types of aluminum alloys and plates used in CNC machining?

There are a variety of aluminum alloys and plates that can be used for CNC machining, each with its own unique set of properties. Cast alloys of aluminum are designated by a four-digit system. The first digit indicates the major alloying element, the second digit indicates the degree of purity for the base aluminum, and the third and fourth digits just designate individual alloys. Aluminum plates are machined products ideal for tooling and base plates.

2024 Aluminum

The 2024 aluminum alloy is an alloy made of copper, magnesium, manganese, and trace impurity elements. It is a high-strength alloy that is frequently used in vehicle and aircraft construction. It has a high strength-to-weight ratio and outstanding fatigue resistance. It can be machined to a high finish and formed with subsequent heat treatment in the annealed condition. Common applications include truck wheels, structural aircraft parts, gears, cylinders, and pistons.

6061 Aluminum

The 6061 aluminum alloy is heat-treatable and flexible while maintaining excellent aluminum characteristics. It has a wide range of mechanical properties and resistance to corrosion. It is weldable, can be brazed with a furnace, and has excellent workability in the annealed condition. 6061 aluminum alloy is used in a wide range of applications, including welded assemblies, marine hardware, aircraft and truck parts, chemical equipment, electronic parts, furniture, fasteners, heat exchangers, heat sinks, and food processing equipment.

7075 Aluminum

The 7075 aluminum alloy has a much higher strength-to-weight ratio than many other alloys, making it ideal for use in high-stress applications. In the annealed condition, this grade can be formed and heat-treated if necessary. Its cost is typically higher than other alloys due to its high strength. Common applications include aircraft fittings, gears and shafts, missile parts, regulating valve parts, worm gears, as well as aerospace and defense applications.

MIC-6 Aluminum Plate

Aluminum MIC-6 is a cast plate known for its stability and consistency between plates, superior flatness and dimensional tolerances on the thickness. Popular for tooling and base plates due to the stability and resistance to wear.

Cast Aluminum Jig Plate

The cast jig plate is a machined plate made from cast aluminum. It is stress-relieved to provide sound dimensional stability and minimal or no distortion, even after extensive machining operations. It is a cost-effective alternative to other alloys. Common applications include tooling, fixtures, and jigs.

What are finishing options for CNC-machined aluminum parts?

There are a variety of finishing options available for CNC-machined aluminum parts, including:

Anodizing

Anodizing is a type of aluminum finishing that creates a protective layer on the aluminum surface. This layer can be dyed to create a wide range of colors.

Painting

Painting is another popular aluminum finishing option. It can be used to create a wide range of colors and effects.

Powder Coating

Powder coating is a type of aluminum finishing that creates a durable, protective layer on the aluminum surface.

Plating

Plating is a type of aluminum finishing that involves bonding a thin layer of metal to the aluminum surface. This can be done for a variety of reasons, including to improve the aluminum's appearance or to protect it from corrosion.

Types of Anodizing for Aluminum Parts

Anodizing is a surface treatment used to thicken the natural oxide layer on aluminum parts. The anodizing process makes aluminum parts more corrosion resistant and wear resistant, and also provides better adhesion for primers and glues than bare aluminum. Anodizing is usually performed after machining aluminum parts, as it can improve the finish of the parts and help protect them from wear.

There are three main types of anodizing for aluminum parts:

Type 1 (Chromic Acid Anodizing)

Creates a thin, protective layer on the aluminum surface. It is often used for parts that need to be corrosion resistant and won't damage or fatigue the aluminum.

Type II (Sulfuric Acid Anodizing)

Creates a thin, protective layer on the aluminum surface that can be dyed to create a wide range of colors.

Type III (Sulfuric Hard Anodizing)

Creates a thicker, more durable layer on the aluminum surface that can also be dyed. With a hardness of up to 70 Rockwell, it is often used for parts that will be exposed to high wear and tear.

What applications is aluminum CNC machining used for?

Aluminum CNC machining can be used for a wide range of applications, including:

- Automotive parts: Aluminum is often used to create lightweight automotive parts, such as wheels and suspension components.

- Aerospace parts: Aluminum is the material of choice for many aerospace applications because of its strength and durability.

- Medical devices: Aluminum is often used to create medical devices because of its biocompatibility and resistance to corrosion.

- Electrical components: Aluminum is a good conductor of electricity, so it is often used to create electrical components, such as wiring and circuit boards.

Why do designers and engineers choose aluminum and aluminum alloys?

There are many reasons why designers and engineers choose aluminum and aluminum alloys for CNC machining. Some of the advantages of aluminum machining include:

- Aluminum is a lightweight material that is easy to work with and transport.

- Aluminum has a high strength-to-weight ratio, meaning it is strong yet light.

- Aluminum is corrosion resistant and does not rust.

- Aluminum has a low melting point, making it easy to work with and shape.

- Aluminum is a good conductor of heat and electricity.

- Aluminum can be recycled and reused.

- Aluminum is a relatively soft metal that is easy to machine.

- Aluminum can be anodized to create a variety of colors.

- Aluminum CNC machining can be used to create parts with intricate designs and detailed features.

Contact our experienced team today.

To learn more about aluminum CNC machining and how we can help you with your next project, contact the experienced team at Mountain Machine Works.

We are proud to offer complete CNC machining services for aluminum parts, including aluminum milling, aluminum turning, and large part machining with aluminum. Our state-of-the-art equipment and experienced team can handle projects of all sizes, from small prototype runs to production orders.

Request a quote today.