Stainless Steel CNC Machining Services

When it comes to stainless steel CNC machining, Mountain Machine Works is a leader in the industry.

We offer a variety of stainless steel CNC machining techniques that will meet your needs, including milling and turning. On this page, we will discuss what stainless steel CNC machining is, the different types of stainless steel used in CNC machining, and the most common stainless steel CNC machining processes. You can also discover why designers and engineers choose stainless steel and stainless steel alloys for CNC machining and milling parts and the advantages of Mountain Machine Works’ complete CNC services with stainless steel.

What is Stainless Steel CNC Machining?

Stainless steel CNC machining is a process of cutting stainless steel materials with computer numerically controlled (CNC) tools. This process involves the use of specialized machinery and software to create custom stainless steel parts for a variety of industries.

The stainless steel parts created with stainless steel CNC machining can be used in many applications, including medical devices, aerospace components, and automotive parts.

Advantages to Stainless Steel CNC Machining

Why Choose Stainless Steel for Your Custom Parts?

Stainless steel is a popular choice for custom parts due to its durability, corrosion and oxidation resistance, and its ability to be machined. It is also a cost-effective material that can be used in a variety of industries and applications.

Stainless steel alloys are commonly used for stainless steel CNC machining because of their high strength, ductility, and machinability.

Common Stainless Steel CNC Machining Processes

When stainless steel is machined with a CNC machine, there are several processes that can be used to create the desired part. These include:

Turning

Stainless steel can be turned on a lathe to create cylindrical parts with even wall thickness and tight tolerances.

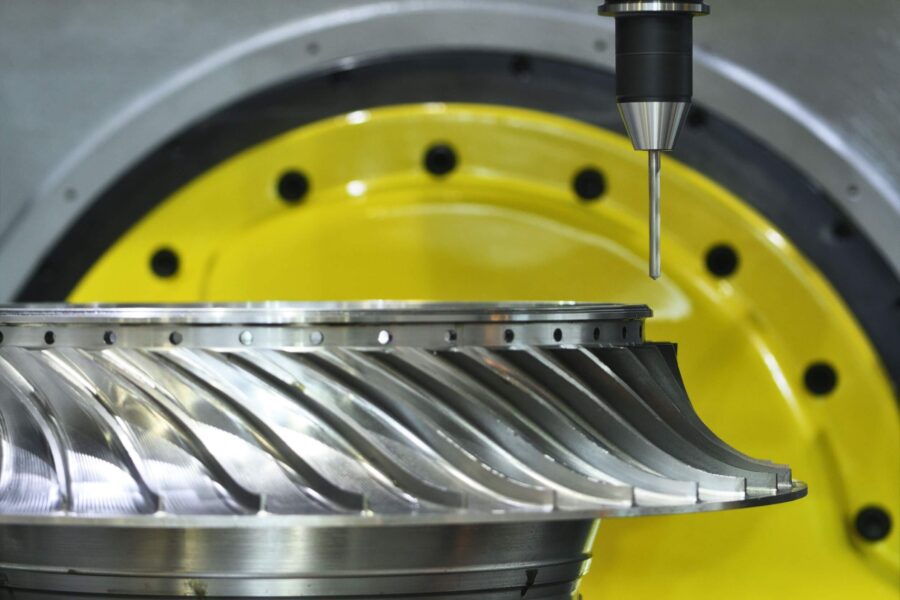

Milling

Stainless steel can be milled using CNC tools to create complex shapes with high precision.

Drilling

Stainless steel parts can be drilled with CNC equipment for added strength or custom features.

Grinding

Stainless steel parts can be ground with a CNC grinder for added precision and strength.

Polishing

Stainless steel parts can be polished to a high shine using CNC polishing equipment.

Tapping

Stainless steel parts can be tapped with CNC tapping tools to create threaded holes.

What are Stainless Steel Alloys?

Stainless steel has become the go-to material for products designed to last. Its secret lies in its powerful composition – a balanced blend of iron and at least 11% chromium that creates a barrier against corrosion and rust, helping it resist deterioration caused by oxygen or other elements.

The combination of different metals allows stainless steel to be engineered for specific applications and industries. Investing in stainless steel means investing in quality you can trust.

Types of Stainless Steel used in CNC Machining

There are several types of stainless steel used in stainless steel CNC machining. The type of stainless steel chosen for the part will depend on its intended use and application. Common stainless steel alloys used in stainless steel CNC machining include:

303 Stainless Steel

A low-carbon stainless steel alloy with good corrosion resistance.

304 Stainless Steel

The most common stainless steel alloy, this material is often used for food processing and medical equipment.

316 Stainless Steel

A high-strength stainless steel alloy with excellent corrosion resistance, making it ideal for harsh environments.

17-4 Stainless Steel

A stainless steel alloy with high strength and good corrosion resistance, making it perfect for aerospace applications.

410 Stainless Steel

A stainless steel alloy that is heat treatable and perfect for high-stress applications.

Inconel

A stainless steel alloy that is resistant to corrosion and oxidation, making it ideal for aerospace and chemical processing applications.

Why choose stainless steel alloys for CNC Machining?

Stainless steel alloys are ideal for stainless steel CNC machining because they are strong, corrosion-resistant, and have excellent heat resistance.

Stainless steel parts created through stainless steel CNC machining can be used in a variety of applications and industries, making stainless steel one of the most versatile metals available.

What Are Finishing Options for CNC-Machined Stainless Steel Parts?

CNC stainless steel parts can be finished in several ways. Depending on the application, stainless steel parts can be:

Polished to a high shine using CNC polishing equipment.

Sandblasted for a matte finish.

Anodized for enhanced corrosion resistance and improved surface hardness.

Powder coated for increased durability and protection from environmental conditions.

Plated with a layer of stainless steel, nickel or other metal for added durability.

Laser engraved with logos, serial numbers, or other text.

Painted with a variety of colors.

Tumbled for strength and improved surface finish.

Coated with epoxy paint or powder coating for improved aesthetics and additional protection from the elements.

Electroplated for improved wear resistance and corrosion protection.

Why Do Designers and Engineers Choose Stainless Steel and Stainless Steel Alloys?

Designers and engineers choose stainless steel and stainless steel alloys for CNC machining because of their superior strength, corrosion resistance, heat resistance, and aesthetic appeal. Additionally, stainless steel parts can be more cost-effective than other metals due to the availability of stainless steel in a variety of grades that can meet different performance requirements.

What Industries Use Stainless Steel Machining?

Stainless steel machining is used in a variety of industries, including:

Aerospace

Stainless steel parts are used in aircraft and spacecraft components, from bearing systems to engine parts.

Medical

Stainless steel is often used for medical devices and equipment due to its strength and corrosion resistance; and is commonly used in medical instruments such as syringes, surgical instruments, and even biopsy needles.

Food Processing

Stainless steel CNC machined parts are often used in food processing machinery due to its non-corrosive properties.

Automotive

Stainless steel is a popular material for automotive parts such as exhaust systems, fuel tanks, brakes, and more.

Marine

Stainless steel parts are often used in marine applications due to its corrosion resistance and strength.

Construction

stainless steel is often utilized for Structural components as well as aesthetic features such as stainless steel staircases, railings, and other architectural elements.

Industrial Manufacturing

Stainless steel parts are often used in industrial equipment due to their strength, corrosion resistance, and heat resistance.

Why Choose Mountain Machine Works for Stainless Steel CNC Services?

Mountain Machine Works offers stainless steel CNC machining services that can create parts with tight tolerances and excellent surface finishes. Our stainless steel CNC machined parts feature:

- High-precision accuracy.

- Quick lead times.

- Excellent surface finish.

- Custom stainless steel parts to meet your exact specifications.

- Full range of stainless steel grades, including stainless steel alloys.

- Surface finishing services such as tumbling and electroplating for additional protection from the elements.

Contact Our Experienced Team Today

Mountain Machine Works has a team of highly skilled professionals who specialize in stainless steel CNC machining and milling parts. Our stainless steel CNC services provide superior accuracy and quality control, with stainless steel parts machined to exact specifications within tight tolerances.

We are committed to providing our customers with stainless steel CNC services that meet their needs, whether it’s stainless steel prototypes, large part machining, or high volume production runs. Our team will work closely with you throughout the entire process to ensure a high-quality stainless steel part that meets your needs.

Contact us today to learn more about stainless steel CNC services and what Mountain Machine Works can do for you.