Titanium CNC Machining Services

If you're looking for titanium CNC machining, look no further than Mountain Machine Works.

Our skilled team provides a variety of titanium CNC machining techniques that will meet your needs.

We’ll explain everything you need to know about titanium and its alloys, why titanium is being used in so many applications, what CNC machining is and how it’s the best manufacturing technique for titanium, what you should consider when machining titanium parts, the variety of surface finishes available and how much CNC machining titanium costs.

What is Titanium CNC Machining?

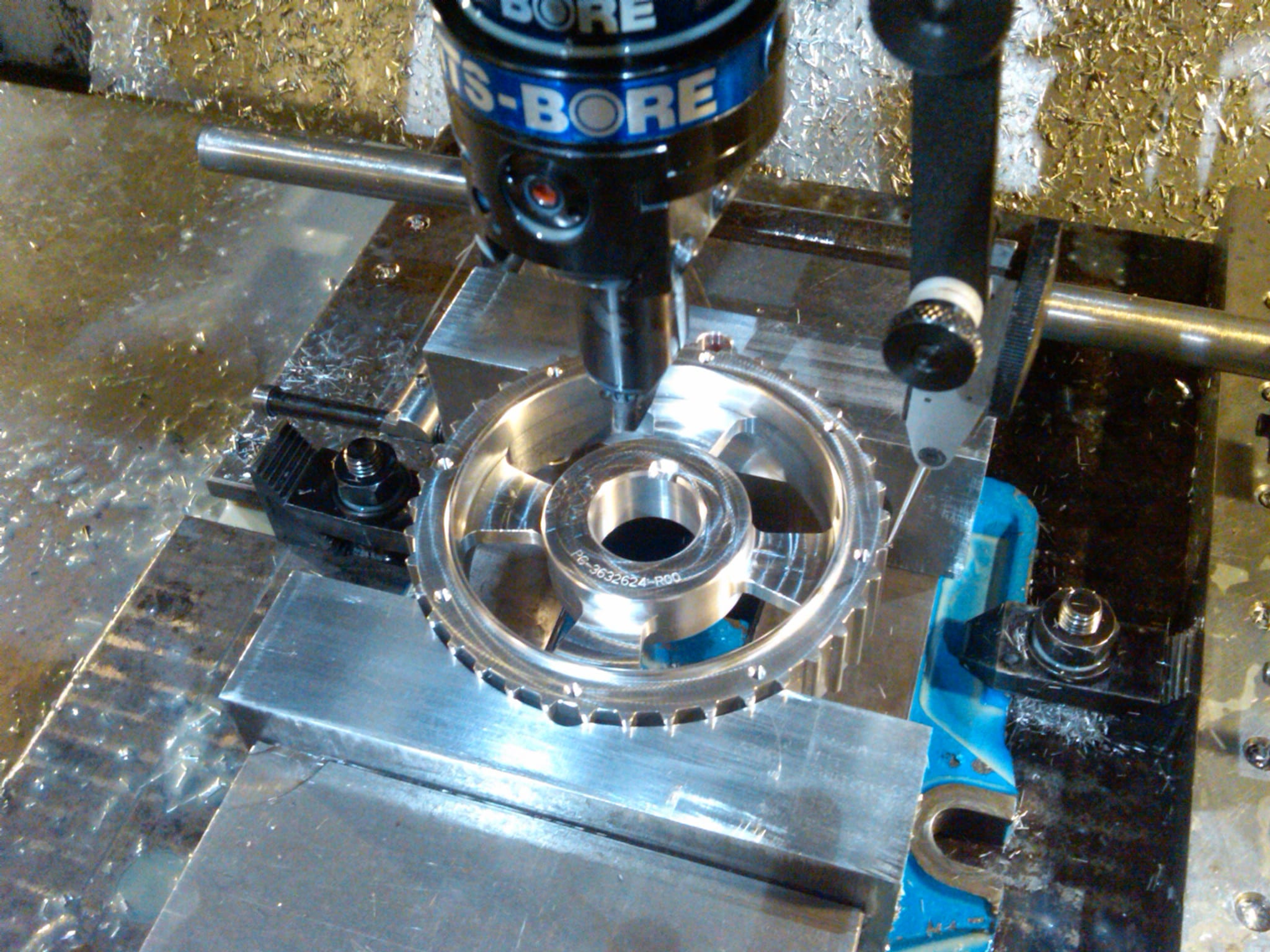

CNC machining is a manufacturing process that uses computerized numerical control to operate machine tools. This means that the machine tools are controlled by computer instead of by hand. CNC machining can be used to create parts from a variety of materials, including metals, plastics and composites. Titanium is one of the most popular materials for CNC machining because it has a high strength-to-weight ratio, making it one of the strongest metals.

CNC machining was developed in the 1950s and has been used extensively in aerospace, medical and automotive applications since then. Today, CNC machining is the preferred manufacturing method for titanium parts because it offers a number of advantages over other methods, such as stamping, casting and injection molding.

Advantages of CNC Machining

Why Choose Titanium for Your Custom Parts

Titanium is a very strong, lightweight metal that is resistant to corrosion and is non-magnetic. These properties make titanium ideal for many applications requiring high strength-to-weight ratio, including aerospace, medical and automotive.

Titanium alloys are even stronger and can be welded, formed and machined. They’re being used increasingly in a variety of consumer products because they offer the same strength and durability as titanium but at a lower cost.

What Are Titanium Alloys?

Titanium alloys are titanium metals that have been combined with other metals to improve their strength, ductility or weldability.

The most common titanium alloy is titanium-aluminum (Ti-Al), which is used in aerospace applications because of its high strength and resistance to corrosion. Other titanium alloys include titanium-vanadium (Ti-V), titanium-molybdenum (Ti-Mo) and titanium-zirconium (Ti-Zr).

What Are the Different Types of Titanium?

There are a number of different types of titanium, including:

Titanium Grade I

Titanium Grade I is the most common type of titanium. It is used in a variety of applications, including aerospace, medical and automotive.

Titanium Grade II

Titanium Grade II is less common than Titanium Grade I. It is used in a variety of applications, including aerospace and medical.

Titanium Grade III

Titanium Grade III is the least common type of titanium. It is used in a limited number of applications, including medical.

What Are the Advantages of Titanium?

Titanium has a number of advantages over other metals, including:

- Titanium is strong: Titanium has a high strength-to-weight ratio, making it one of the strongest metals.

- Titanium is light: Titanium has a low density, making it one of the lightest metals.

- Titanium is corrosion resistant: Titanium is highly resistant to corrosion, making it an ideal metal for many applications.

- Titanium is biocompatible: Titanium is non-toxic and is compatible with the human body, making it an ideal metal for medical applications.

- Titanium is non-magnetic: Titanium is non-magnetic, making it an ideal metal for many applications.

What Are the Disadvantages of Titanium?

Titanium has a number of disadvantages over other metals, including:

- Titanium is expensive: Titanium is one of the most expensive metals.

- Titanium is difficult to weld: Titanium is difficult to weld, making it challenging to work with.

- Titanium is difficult to machine: Titanium is difficult to machine, making it challenging to work with.

Factors to Consider in CNC Machining of Titanium

There are a number of factors to consider when CNC machining titanium, including:

Titanium alloys

There are a number of different titanium alloys that can be used for CNC machining. Each alloy has its own set of properties that will affect the machining process.

Titanium grades

There are three grades of titanium that are commonly used for CNC machining: Grade I, Grade II, and Grade V. Each grade has its own set of properties that will affect the machining process.

Titanium hardness

Titanium is a relatively soft metal, which makes it easy to machine. However, titanium can be heat treated to increase its hardness.

Titanium density

Titanium is a relatively dense metal, which can make it challenging to machine.

Titanium cost

Titanium is a relatively expensive metal, which can make CNC machining titanium parts costly.

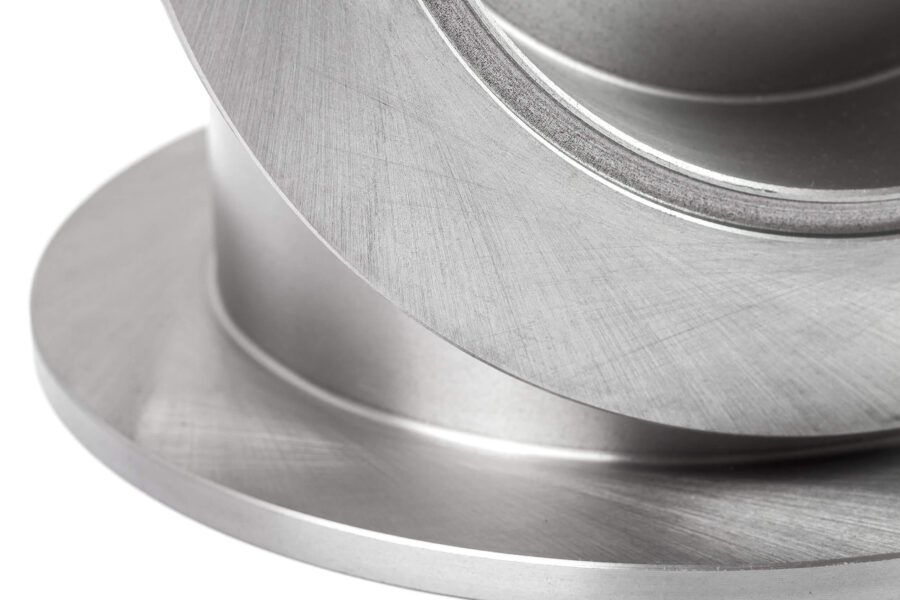

What Surface Finishes Are Available for Titanium?

There are a number of surface finishes that can be applied to titanium, including:

- Anodizing: Anodizing is a process that creates a thin film on the surface of titanium. This film can be used to improve the appearance of titanium, or to protect it from corrosion.

- Polishing: Polishing is a process that creates a smooth, mirror-like finish on the surface of titanium.

- Passivation: Passivation is a process that creates a thin film on the surface of titanium. This film helps to protect titanium from corrosion.

- Painting: Painting is a process that can be used to improve the appearance of titanium.

- Brushed: Brushed is a process that creates a textured finish on the surface of titanium.

What Are Some Applications for Titanium CNC Machining?

Titanium CNC machining can be used for a variety of applications, including:

Aerospace

Titanium is often used in aircraft and aerospace applications because of its high strength-to-weight ratio.

Medical

Titanium is often used in medical devices and implants because of its biocompatibility.

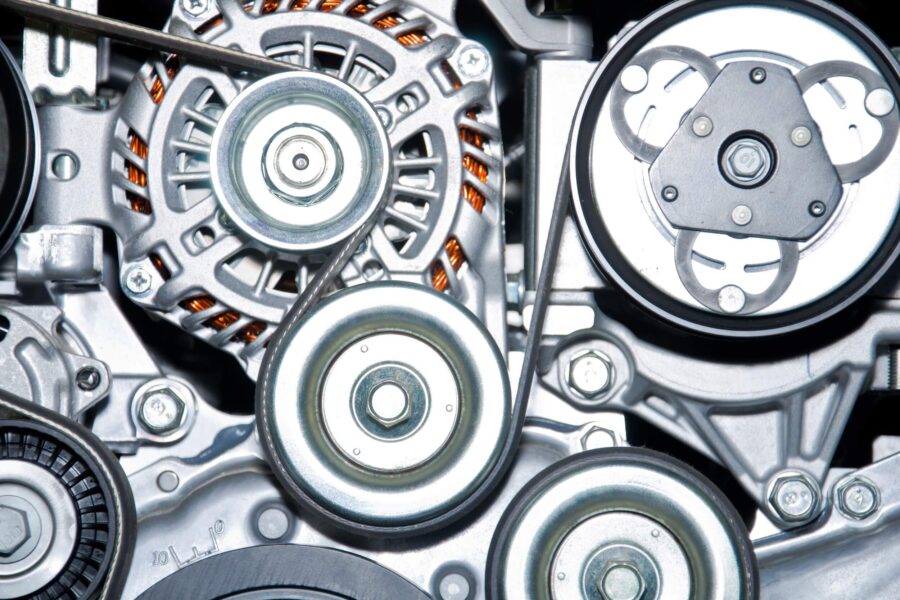

Automotive

Titanium is often used in automotive applications because of its strength and light weight.

Other Applications

Chemical Processing

Titanium is often used in chemical processing because of its corrosion resistance.

Marine Applications

Titanium is often used in marine applications because of its corrosion resistance.

Power Generation

Titanium is often used in power generation because of its high strength-to-weight ratio.

Oil & Gas Applications

Titanium is often used in oil and gas applications because of its corrosion resistance.

Food Processing

Titanium is often used in food processing because of its non-toxic properties.

Desalination

Titanium is often used in desalination because of its corrosion resistance.

What to Look for in Titanium CNC Machine Shops?

When looking for titanium CNC machine shops, it’s important to consider the following:

- The shop should have experience machining titanium.

- The shop should have a variety of CNC machines, including lathes and mills.

- The shop should use high-quality cutting tools.

- The shop should have a clean, well-organized facility.

- The shop should meet your application requirements, such as having the ability to machine large parts.

Mountain Machine Works meets all of these requirements.

Contact Mountain Machine Works today

If you're looking for the best titanium CNC machining, look no further than Mountain Machine Works.

The highly skilled team at Mountain Machine Works provides a variety of Computer Numerical Control (CNC) machining techniques for titanium at our well-equipped 12,500-square-foot facility in Auburn, Maine.

Contact us today to learn more about our titanium CNC machining services or to request a quote.