Maine’s Precision OEM CNC Machining

Fast, Reliable, and All Under One Roof

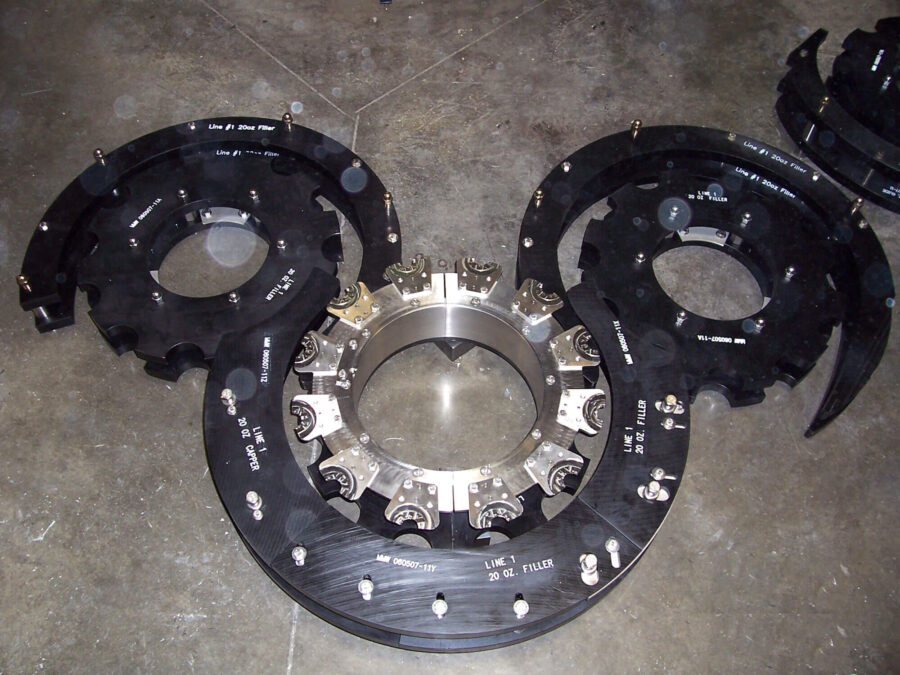

As your one-stop-shop for all machining and prototyping, Mountain Machine works has innovative CNC technology and in-house equipment to deliver solutions that meet your needs while adhering to OEM specifications. From large part machining to tight tolerance parts, thin wall turning, and shafting, we can take care of all your machining needs in house with a single point of contact for your project.

Partner with Mountain Machine Works for advanced CNC machining and prototyping, all handled in-house by Maine’s trusted experts. For over 40 years, we’ve delivered custom OEM parts with rapid turnarounds, tight tolerances, and unmatched quality—helping you meet your specs, your timeline, and your budget.

Get a Quote Today — Call (207) 783-6680

Quality, Durability & Cost Savings—Guaranteed

- Full Project Lifecycle: From initial design and prototyping to production runs—handled start to finish in our Maine facility.

- Custom Machining for Every Need: We specialize in OEM-specific solutions, including tight tolerances, custom materials, and complex geometries.

- Fast Turnaround: Most projects ship in just 3–5 weeks, helping you keep production on schedule.

Our shop can handle every step of the project’s lifespan from the initial design to final product run, helping you create larger components with reliable, OEM-specific parts.

In our line of business, every project is unique, and many customers require customized solutions to fit specific OEM requirements without compromising efficiency or durability. We bring that understanding to the conversation and work closely with you to understand your specific needs.

From material preferences to minimum tolerances and ideal surface finishes, we can tailor each product design to fit your needs. Our engineers ensure your part is durable and high-quality, while also looking for potential cost savings along the way.

From Initial Design to Final Product Run

At Mountain Machine Works, our engineers are experienced in providing the highest quality OEM parts possible, helping you save money and lower costs throughout the design and prototyping phase.

With a customer-centric approach, we work directly with you to produce the most refined product possible, ensuring the highest quality work with the lowest costs to you. By the end of the product line, you can see your original vision translated into a meticulously crafted final product that exceeds expectations.

We pride ourselves in creating a long-term customer partnership for your recurring machining needs. With everything handled under one roof, we do not need to outsource to other shops, ensuring the highest quality at every step.

Why Choose Mountain Machine Works?

We understand the importance of delivering OEM parts that not only meet your specifications, but also help you save money and lower costs during the design and prototyping phase.

- 40+ Years Serving Maine’s Manufacturers

- All Work Performed In-House—Never Outsourced

- Dedicated Project Managers & Engineers

- Average Lead Time: 3–5 Weeks

- Transparent Quotes & No-Surprise Pricing

Ready to bring your OEM part to life with precision and reliability? Let’s talk about your project.

Contact us today for a free, no-obligation quote:

From optimizing the designs and materials throughout the manufacturing process, we can help you create the most refined product possible without compromising quality.

Through our quality work, we build long-lasting partnerships with our customers, striving for excellence in every product run. If you’re ready for a machining partner to help you produce OEM CNC machining parts under one roof, get in touch today. Let’s discuss how we can bring your vision to life with perfect precision.

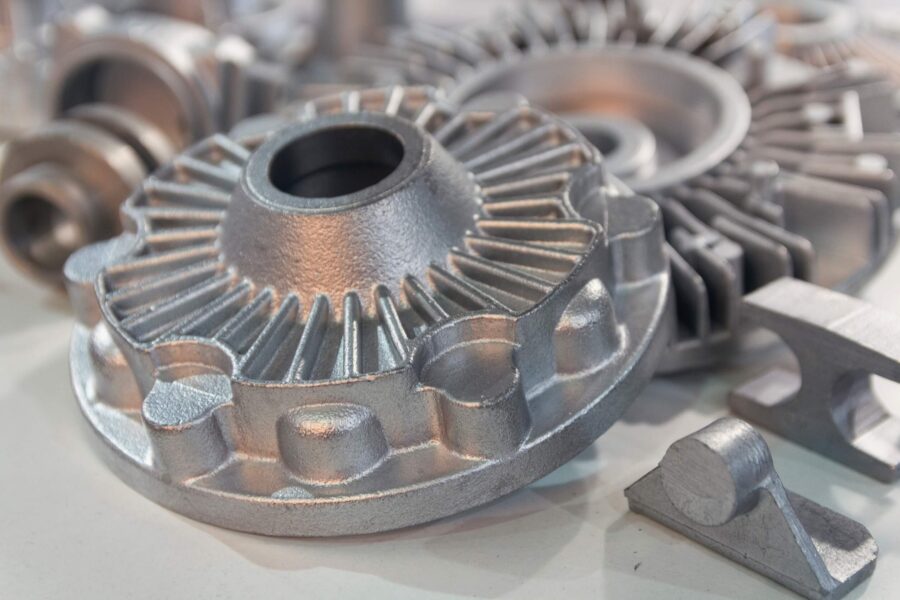

Materials We Work With

No matter how difficult the part or material is, we are here to help you design and machine each part from start to finish. Our team crafts precision parts that push the envelope of standard machining quality.

Titanium

Titanium is strong yet extremely lightweight. Because of its easy-to-clean and biocompatible properties, it is a popular metal for use in medical and healthcare applications.

Plastics

Plastics are present in almost every industry today, replacing more expensive parts for with an affordable alternative.

Aluminum

An affordable and lightweight material, aluminum is also known for its resistance to corrosive materials. While not as durable and hard as steel or titanium, it is extremely easy to machine, making it a popular choice for quality parts.

Stainless Steel

Used in various industries, stainless steel is excellent for corrosion resistance, strength, and durability. This material is popular for demanding applications that need resistance to rust or acidic environments.

Molybdenum

As a popular material for aerospace, energy, and electronics industries, this metal is known for its heat and corrosion resistance. It has a high tensile strength similar to steel, but it can be difficult to machine so it is not as widely available.

Ductile Iron

Ductile iron is a popular choice for its resistance to wear and tear. It is highly machinable, making it a popular choice. Providing the strength and durability of cast iron, this metal is treated with magnesium to make it more ductile and flexible.

Cast Iron

This is a strong, durable material that can withstand a large amount of stress and wear during everyday use, while remaining machinable enough to use it for complex parts. Cast iron and ductile iron are materials that few shops handle because of its dustiness and difficult handling, however, Mountain Machine Works has processes in place to manage these problems, making these materials a breeze to work with.

Super Alloys and Special Metals

When your project demands advanced performance in extreme conditions—whether it’s heat, corrosion, or strength—super alloys and special metals deliver exceptional results.

• Hastelloy

• Kovar

• Inconel

• Tungsten Alloys

File Formats We Accept

What if you don’t need to start with a product design and prototype because you already have the drawings or design requirements for your parts? At Mountain Machine Works, we are happy to start with your design. We can accept files in any of the following formats:

- AutoCAD (DXF, DWF)

- Pro Engineer (DRW, PRT, XPR)

- SolidWorks (SLDPRT, SLDDRW, SLDDRT)

- Parasolid (XT, XB)

- Portable Document Format (PDF)

- And others

All Necessary Certifications to Work on Your CNC Machining Project

As a one-stop machining shop, we understand it’s necessary to comply with necessary codes and regulations. Our team has all the necessary certifications required to work on your OEM CNC machining parts, including:

-

ISO 9001 Certification

-

ITAR Registration

You can rest assured knowing every project is handled with the utmost care and attention to quality and security. Ready to meet any machining challenge, we take pride in the precision work we do both in the machine shop, and in our paperwork.

Want to check on the status of a particular certification from Mountain Machine Works? Get in touch and let us know what you are looking for. We are happy to learn more about your project and accommodate your request.

How Much Does It Cost to Have Parts CNC Machined?

The average machining order from design to final run can start at $3,000 and up. A true estimate requires more information about your product, the specific design requirements, and the size and number of parts. To get more information about CNC machining costs, get in touch today and let us know how we can help you bring your vision to life.

Industry Applications of OEM Machined Parts

Mountain Machine Works is a trusted US-based provider of precision CNC machining, custom fabrication, and large-part manufacturing services. We have extensive experience serving a wide range of demanding industries, with a primary focus on the following sectors:

- Government & Military (ITAR Registered): As an ITAR registered machine shop, we are fully compliant and experienced in manufacturing sensitive and mission-critical components for defense, military, and government projects, ensuring strict adherence to all specifications and security protocols.

- Medical Device & Life Sciences We provide high-precision machining for the medical industry, manufacturing components for medical devices, surgical instruments, and orthopedic implants where tight tolerances and superior surface finishes are critical. Our ISO 9001 certified quality system ensures that every part meets the stringent demands of the life sciences sector.

- Power Generation: We provide custom machined parts for the power industry, including components for turbines, generators, and infrastructure. We work with specialized alloys to meet the high-temperature and tight-tolerance demands of energy production.

- Commercial & Industrial: From one-off prototypes to full production runs of OEM parts, we support diverse industrial applications. We are a key supplier for manufacturers requiring reliable, high-quality machined components for their own product lines.

- Robotics & Automation: We are at the forefront of the robotics and automation revolution, machining the complex components that power modern industry. We produce everything from structural frames for automated manufacturing lines to high-precision end-effectors (grippers) for custom robotic arms, helping our clients build the future of technology.

Whether your project requires complete large-part machining or high-volume production of smaller OEM machined parts, our team has the expertise and equipment to deliver.

Using Only the Best Materials for Your OEM Parts

In many industries, the best repair and manufacturing experience comes with using OEM parts. Not only are these parts more reliable and durable, but they don’t require frequent replacement. These parts undergo regular testing and quality assurance procedures, which means you need a machining shop who uses only the best materials.

No matter what materials you are working with, from aluminum to titanium, cast iron, or molybdenum, our shop can handle it all.

What Types of Products or Components Can Be Made with CNC Machining?

With our advanced CNC machining capabilities, we produce a wide array of custom components to suit the specific needs of today’s most demanding industries. Below are just a few examples of what we regularly manufacture for our clients:

Aerospace, Government & Military

As an ITAR-registered shop, we produce mission-critical components that meet stringent mil-spec requirements. This includes everything from airframe structural components and turbine blades to durable housings for avionics and defense systems.

Medical Device & Life Sciences

We manufacture parts where precision is paramount. From intricate surgical tools and orthopedic implants to durable housings for diagnostic machines, our processes deliver the tight tolerances and reliable repeatability the medical field demands.

Robotics & Automation

We build the backbone of modern automation. Our capabilities are ideal for creating custom robotic arm components, high-precision actuator housings, and specialized end-effectors (grippers) for a variety of automated manufacturing and logistics applications.

Power Generation & Energy

We support the energy sector by manufacturing robust components built to withstand extreme conditions. This includes parts for turbines, custom housings and enclosures, durable shafts and couplings, and specialized fittings for energy infrastructure.

Commercial & Industrial Products

Our versatility allows us to serve a broad range of commercial needs. This includes industrial tooling, dies, and fixtures for manufacturing processes, precision mechanical assemblies (gears, brackets), custom architectural components, and durable hardware for consumer products and retail displays.

If your project requires precision, consistency, and quality—no matter how specialized or complex the part—our shop is equipped to deliver.

Talk to Us About Your Project Today

Ready to start a conversation? Let’s talk about your project vision and requirements. Our team starts with a consultation to ensure we understand your project and can provide the best insights during the design and prototype phase.

Before you know it, we’ll help you turn your initial vision into a real product with quality OEM CNC machined parts.